-

1 - High Efficiency Atmospheric-Breathing Electric Propulsion

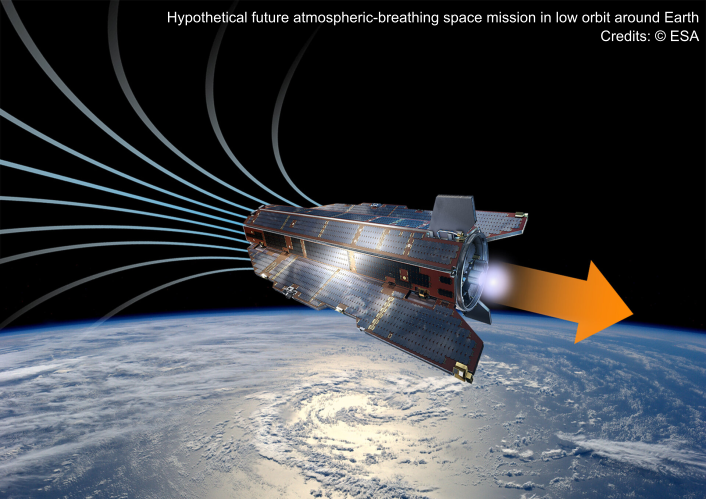

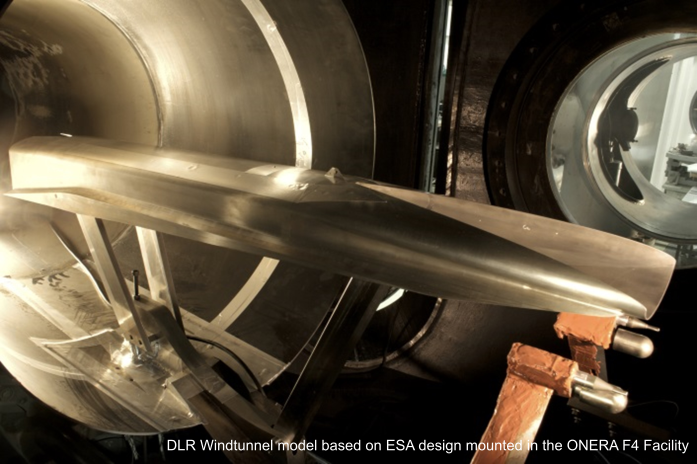

Atmospheric-breathing electric propulsion systems are defined by their capability to generate thrust using as propellant the gases of the atmosphere, which are collected by an intake installed on the same platform. They are capable of operating with variable atmospheric gas mixtures and densities, and resilient to long term operation in a challenging environment. This topic targets innovative electric propulsion systems with high thrust-to-power and high-specific-impulse capability.

-

2 - Advanced Airbreathing Propulsion

Generating lift by means of atmospheric flight while ingesting the atmospheric oxidizer into the airbreathing engine results into an overall lighter flight vehicle: there is no need to carry the oxidizer and the related storage system on board and the high aerodynamic efficiency L/D > 1 lowers further the required thrust with respect to classical non-lifting vehicles.

The main applications are to first stages of launchers, replacing the booster function and potentially performing some of the duty of subsequent stages, or suborbital point-to-point transports. Owing to a wide flight regime, potentially from Mach 0 to about 12, the vehicle and its propulsion must perform in an ample operational range. This challenges the design of the propulsion system, which may incorporate variable geometry elements to enlarge the operational regime of the:

- Air intake and isolator

- Compressor: ram- or turbo based

- Combustor and injectors

- Nozzle and thrust vectoring

As an alternative to the multi-mode variable cycle engine, an engine integrating different propulsion elements can also be considered, e.g. a turbine- or rocket- based combined cycle engine and a (sc)ramjet which provides the required operational range.

In either case of a variable cycle engine or a combination of propulsion systems, the following design aspects have a critical impact in the overall performance of the vehicle:

- The transition between modes of operation, e.g. turbo to ramjet or ram to scramjet.

- The overall integration of the propulsion system in the vehicle.

- The combined aerothermal and aerodynamic loads throughout the mission.

- The overall thrust-to-drag (aero-propulsive) balance to assure net thrust and acceleration.

- The various combustion regimes.

- The internal flow path design from an aero-thermo-mechanical-structural point of view.

- The design and integration of the variable geometry components, e.g. intakes, throats and nozzles, by translation, deflection or morphing of the structural elements.

-

3 - Rotating and Pulse Detonation Propulsion

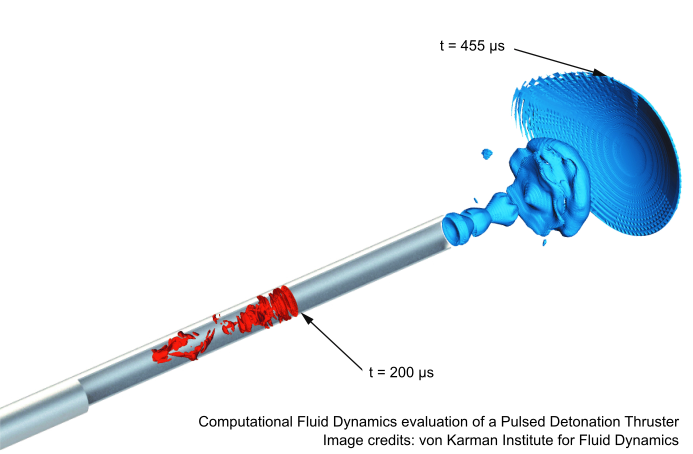

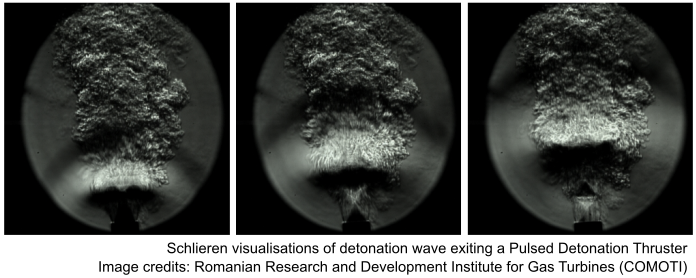

Detonative propulsion engines exhibit superior performance in terms of specific impulse than conventional liquid, hybrid or solid rocket engines. In addition, the pressure gain combustion offers the advantage of lowering the required injection pressure, thus potentially benefiting from an overall reduction in system mass. There are two approaches to realise detonative combustion in a propulsive system: pulse detonation and rotating detonation. Both concepts have the potential of simplifying and reducing the weight of the current propulsion systems. Although the research on detonative combustion started more than half a century ago, the needs of more affordable and efficient propulsion system justify this breakthrough.

-

4 - Water Propulsion

Water propulsion systems are currently being developed for various applications. In the search for non-toxic, non-carcinogenic and in general non-hazardous replacements of hydrazine, water is the ultimate green propellant. While the specific impulse can be better than that of other monopropellants, the main advantage is the removal of hazards, such as toxicity and adiabatic decomposition of hydrazine. The water is not toxic nor carcinogenic and therefore handling is by definition as safe as, or even safer, than that of any other conceivable green propellant.

The main advantages of water propulsion are thus on the one hand the safe storability of the propellant in form of the stable reaction product, water. Water is however also a substance which can be found, in solid state, in various places in the solar system (comets, lunar poles, Martian soil, etc.). The concept of water propulsion is therefore, beyond the immediate applications as hydrazine replacement in LEO satellites, potentially very useful in future exploration missions, employing a simple form of In-Situ Resource Utilisation (ISRU), with only limited propellant processing equipment required.

Several different types of water propulsion exist, with possibly the most common current application being Water-Resistojets (WR). This type of thermo-electric propulsion uses the water itself as propellant. In contrast Water Electrolysis Propulsion (WEP) employs an electrolyser to generate the actual propellants oxygen and hydrogen from the stored water. The two gases are then used to operate conventional chemical propulsion thrusters. Other concepts, like water electrolysis Hall Effect Thrusters (HET) using oxygen and hydrogen for electric propulsion, are also currently under development.

-

5 - Long Term Storability and Operation of Hydrogen Peroxide

Hydrogen peroxide was developed as a propellant for missiles in the 1940s and 1950s until it was replaced by higher performing combinations of propellants, such as hydrazine in the case of satellites, or cryogenically stored liquid hydrogen / liquid oxygen for launchers. Since the 1990s, hydrogen peroxide development for thrusters (in particular small thrusters in the 5N class) has enjoyed a renaissance of activity, as the desire for non-toxic propellants for spacecraft has increased.

Pure hydrogen peroxide will naturally decompose into water (steam) and oxygen given the right catalyst. Stabilisers are added to the hydrogen peroxide to facilitate the storage and allow the safe use as propellant, thus reducing the purity. These additives have the undesirable effect of reducing the propulsive efficiency, hence their use needs to be minimised wherever possible. In launch vehicle and other short term applications, a cumulative increase of pressure can be vented overboard to prevent over pressurisation of the storage tanks. Nonetheless, this is not desirable, or even nor possible in some cases, for multi-year mission satellites. The traditional materials used on satellites, such as titanium alloys and some stainless steels, facilitate the decomposition of hydrogen peroxide and therefore are not suitable in their current form for the long term storage of hydrogen peroxide based propellants.

In order to use hydrogen peroxide for long term applications, alternative materials for components and / or alternative stabilising additives need to be used.

-

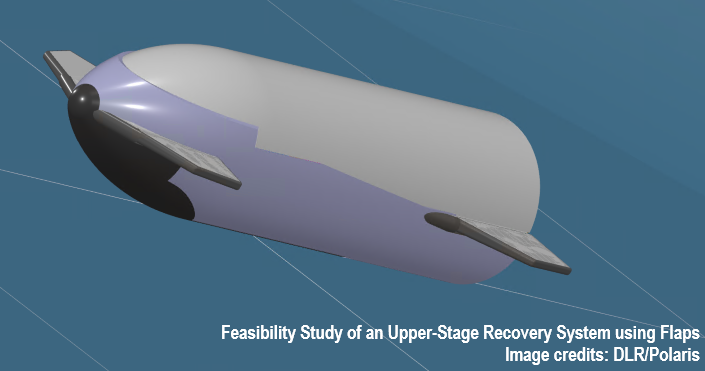

6 - Innovative Aerodynamic Surfaces

The topic of innovative aerodynamic surfaces comprises ailerons, elevons, flaps, rudders, or panels that modify the aerodynamic characteristics of a vehicle and produce lift and drag forces.

Several categories of aerodynamic surfaces are envisaged, subdivided between primary surfaces and complementary surfaces. Primary surfaces are ailerons, elevators, and rudders. Ailerons are mounted on the trailing edge of the flying vehicle and move in opposite directions. Elevators are a moveable part of the horizontal stabilizers, hinged to the back of the tail of the flying vehicle. Rudders are mounted on the trailing edge of the vertical stabilizer, part of the empennage. Complementary surfaces are spoilers, flaps, slats, and airbrakes. Spoilers are used to disrupt the airflow and reduce the lift whereas flaps and slats are used to increase the lift of the flying vehicle. Airbrakes are used to increase drag.

This topic focus on the conception, architecture design, technical analysis, development, and operations of Innovative Aerodynamic Surfaces as propulsive mean for a flight vehicle.

-

7 - Long-term In-space Cryogenic Propulsion and ISRU Propellants

The higher performance of cryogenic propellants and the ubiquity of their precursor availability in the solar system means that they are perfectly suited for in situ resource utilisation (ISRU) and in-orbit refuelling. Many lunar and Martian missions in particular hope to exploit these propellant options. These mission concepts include:

- Martian and Lunar transit stages

- Propulsive Landers

- Space Tugs

- Refuelling stations

Such systems must withstand thermal environments for transfers to Mars / Moon and back, including long duration transfers up to 6 months and dwell time of ~12-24 months. Current cryogenic approaches are limited to the much shorter lived applications for launch vehicles. The requirements for the in-space applications for these propellants will require a significant overhaul of both our understanding of cryogenic propellant management and the product catalogue that has been evolved to exploit them.

The scale of these engines will be similar to, or smaller than existing upper stage engines (~100kN) However they will have additional challenging requirements: large number or restarts/reusability, deep thottleability, and clustering of engines for higher thrusts (in applications such as landers and large transfer stages).

To realise a long-term cryogenic propulsion system several key technologies and operational concepts need to be addressed including: low/zero boil off technologies, cryofliud handling and management, thermal management of temperature distribution within the tanks and zero/low consumption chill down in preparation for engine operation.

-

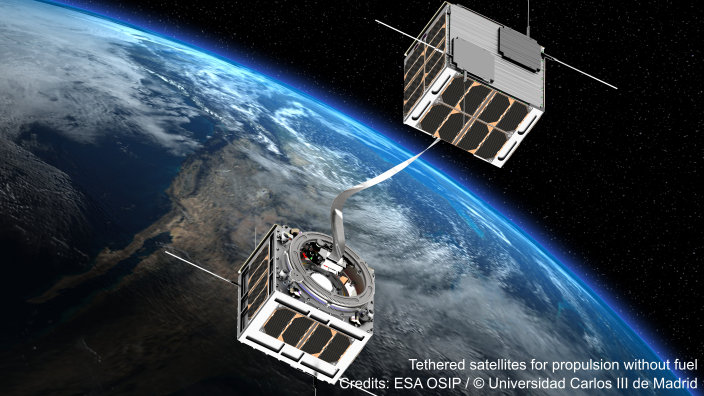

8 - Space Tethers

Space tethers are long, strong, charged cables which can be used for propulsive manoeuvres in space thanks to their interaction with charged particles present in the high layers of the atmosphere and in the solar wind. Their working principle allows for propellant-less orbital transfers or de-orbiting satellites at the end of their life.

-

9 - Beamed Energy Propulsion

A variety of different concepts for space transportation systems with Beamed Energy Propulsion (BEP) engines were proposed in past studies by several different authors. They can be roughly grouped in the following categories:

-

Plasma: The incoming beamed energy is focused by a mirror system. In the focal point on-board propellant or ambient air is converted into plasma. The ejected plasma propels the vehicle by momentum exchange. Laser ablative propulsion, where the target spacecraft or space debris is ablated to create an impulse, also falls in this category.

-

Thermal: A heat exchanger in the vehicle is heated by beamed energy. The heat is transferred to on-board propellant, which is ejected in a classical convergent-divergent nozzle. A special form of thermal beamed energy propulsion is the solar thermal propulsion stage, where the beam source is the sun.

-

Sail: The beamed energy is reflected by a sail. The resulting radiation pressure exacts a force on the vehicle. The Solar Sail is a specific concept of this category, using the pressure of the solar light for propellantless propulsion.

-

Climber: The climber type is a vehicle for a space elevator type transportation system. The climber will convert beamed energy into mechanical energy used for climbing the tether to the orbital destination station.

While the Sail is a feasible approach for in-space applications only, the Climber is a radically different concept and difficult to compare with other propulsion systems.

-

-

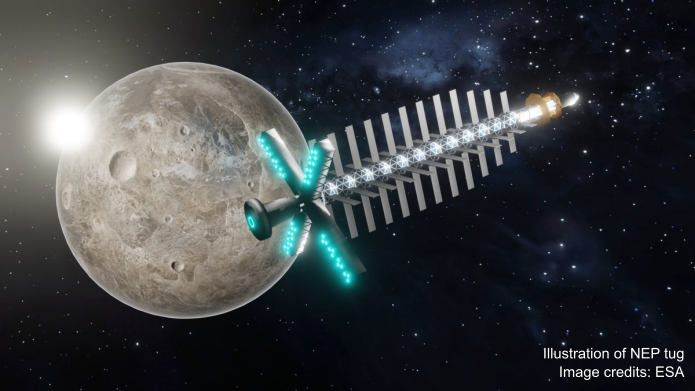

10 - Nuclear Electric Propulsion

Space nuclear electric propulsion (NEP) is a technology that utilizes nuclear reactions to generate electricity and propel spacecraft using electric propulsion (EP) thrusters. The idea of using nuclear energy for space propulsion dates back to the 1950s, with the development of nuclear thermal rockets or nuclear power reactors by the US and the Soviet Union. Since then, various countries and organizations have conducted research and development in NEP as it could revolutionize space exploration by enabling faster and more efficient travel through space. Potential applications of NEP include Earth-Moon space tugs, manned missions to Mars, deep space exploration, asteroid mining, or even satellite servicing and maintenance.

-

11 - Nuclear Thermal Propulsion

In the 1960s and 1970s extensive research on nuclear propulsion was performed by the United States of America and the Soviet Union. Due to financial constraints and a shift in focus, this research did ultimately not lead to operational systems. Meanwhile a lot of progress has been made, not only in reactor technology, but also in material science.

Future exploration and science missions with large payload mass and at the same time high delta v demand, can often not be fulfilled by either the available high specific impulse electric propulsion or the available high thrust chemical propulsion. Already in the early stages of space exploration it became clear that nuclear propulsion and power are key enabling technologies for an extended human presence on moon or Mars.

Recently NASA and DARPA announced the plans for a nuclear thermal propulsion demonstrator (DRACO) to be launched within fiscal year 2027.

-

12 - Metallic Propellant for Chemical Propulsion

The potential use of metals can be exploited not only as a fuel for space vehicles but also as a motivating and promising technology for future “settlement plans” on the Moon and Mars.

The prominent features of metal fuel technology are:

- It offers a completely CO2-free way to produce heat and/or electrical power and to store energy for deferred uses;

- It is a safe commodity for trading large energy stocks across the world, thanks to its intrinsically high energy density value;

- It relies on existing infrastructures, does not require large investments for new power plants, and does limit to the bare minimum its environmental footprint;

- It is based on a large and practically unlimited resource of fuel food stock and on a fully reversible way to recycle the combustion products in an environmentally friendly manner;

The main goal of this technology is to zero the CO2 emissions in the production and recycling processes, as well as in storing and trading energy reserves and assets.

The prospective propellants are:

-

Magnesium powder: With the compromise of specific impulse, ignition condition, combustion rate and sufficiency, powdered magnesium is considered as most promising fuel adopted for Mars or Moon Mission based on ISRU. This has huge challenges in terms of feeding powder to a chamber for combustion. Nonetheless, it could be interesting from an in situ resource utilization perspective in that, if the ISRU processes can convert, for example, lunar regolith metal oxides to metal (e.g. magnesium) and oxygen, these can be used as propellants or an energy source and would be 100% locally sourced. Besides, huge abundance of magnesium oxyde mineral in Martian regolith has been discovered, which makes the production of magnesium powder on Mars to be possible in the future.

-

Aluminium powder: In energetic applications, such as propellants, pyrotechnics and explosives, aluminium is widely used because of its high combustion enthalpy, easy availability, low toxicity and good stability. Aluminium, whether powders or flakes, is used to increase the energy and raise the flame temperature in rocket propellants.

-

Hydrogen: Physicists Wigner and Hungtinton predicted that hydrogen could turn into an electricity-conducting solid metal at the right temperature and pressure. Metastable metallic hydrogen would be a very light-weight, low volume, powerful rocket propellant. Indeed, for comparison, liquid (molecular) hydrogen-oxygen used in modern rockets performs with an Isp of ~460 s whereas metallic hydrogen has a theoretical Isp of 1700 s. Nonetheless, producing the pressure required to reach that state is extremely complex. Currently, several laboratories across the world are working with a Diamand Anvil Cell, in which two opposing diamonds with flattened tips squeeze a thin rhenium gasket. Although there are some promising results, this technology is not mature for industrial production of metallic hydrogen.

-

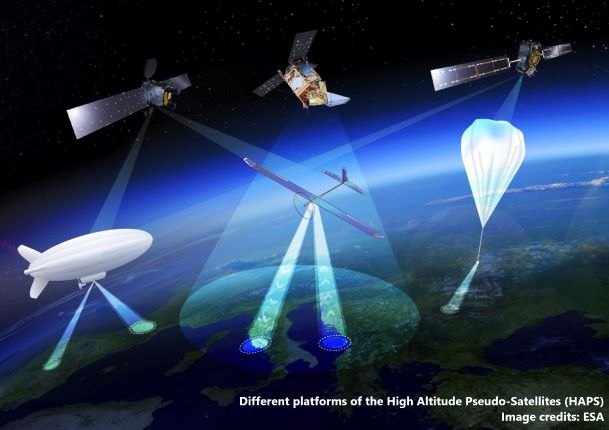

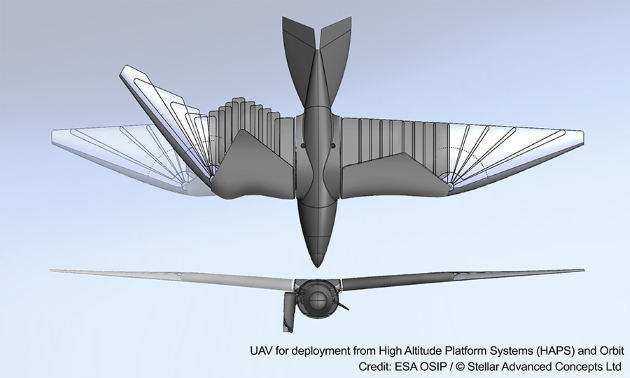

13 - Advanced High Altitude Platform Systems (aHAPS)

High-Altitude Platform Systems or High-Altitude Pseudo-Satellites are flying vehicles able to fly and/or hover at high altitudes above 20 km in the Earth atmosphere. They can operate as Very Low Earth Observation (VLEO) flight vehicles, and are considered as pseudo- or atmospheric-satellites. Their main applications are telecommunications, weather monitoring, and surveillance, similarly to LEO satellites. Another significant application, distinguishing them from conventional LEO satellites, is using them as carrier vehicles for air-launched rockets, making use of the high altitude the flight vehicle can reach. These systems can be in the form of airships, balloons, and airplanes. This topic will evolve around the Flight Vehicle Engineering of such systems, specifically on the advanced propulsion and enhanced aerothermodynamics, making them more efficient while increasing their versatility and performance.

-

14 - Innovative Propulsion on Non-Terrestrial Bodies

Non-Terrestrial bodies come either with or without an atmosphere where propulsive systems and units would relate to landers or observation vehicles (e.g. drones…)

In absence of an atmosphere, one would rather need rocket engines to translate a craft both horizontally and vertically. In the presence of an atmosphere, one can exploit it to generate lift or to hover by means of aerodynes and aerostats.Within the class of aerodynes, one can distinguish between rotorcraft or fixed-wing planes. In both cases, lift is generated by fluid-dynamic forces which carry the weight whereas the propulsion system generates the thrust to compensate for the drag and provide the acceleration.

For aerostats, e.g. balloons, dirigibles…, lift is generated by buoyancy, while lateral translation is generated by wind (drag) or a propulsion unit. This propulsive unit can either make use of the atmosphere by means of e.g. an electrical driven fan, an oxidizer breathing engine, a fuel breathing engine... or fall back to a rocket engine not relying on the atmosphere.

Finally, among these different propulsion innovations, one should assess what power sources feed the engine, namely electrical (photovoltaic or nuclear), chemical (mono- or bi-propellant), ‘fluid’-breathing (using the species in the atmosphere), where the chemical propellant might be coming from an ISRU plant.

Choose timezone

Your profile timezone: